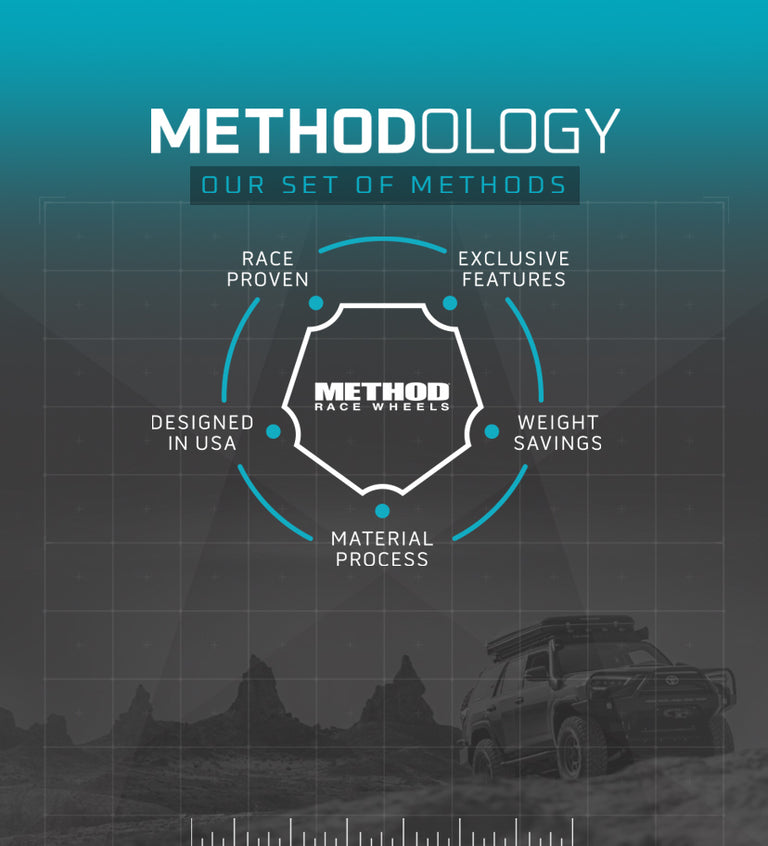

FORGED WHEELS - THE STRONGEST AND LIGHTEST ON THE MARKET

WHAT IT IS:

The difference between cast, flow formed, and fully forged wheels is all in the manufacturing process – and the effect it has on the end result. It starts with a solid chunk of aluminum, the billet is exposed to high heat and then shaped via extreme pressure. The wheel is then drilled, machined and final touches are done.

WHY IT’S OFF-ROAD PROVEN:

All these material properties allow for wheels to be built lighter than a cast wheel of the same design and retain the same or greater load capacity. Additionally, they are more durable with greater safety. Professionals in competitive racing want the best in performance, quality, and safety. For any situation where the wheels are under duress, forged is always the best choice.